Some customers may have questions about how to judge the quality of the dust-free cloth. The cleanliness of the produced dust-free wipes is the key to judging the quality of the wipes. The cleanliness directly affects the decontamination ability of the dust-free wipes. Generally, the cleanliness of a dust-free wipe is defined in the following aspects: 1. The amount of dust generated by the dust-free wipe. Includes dust particle release (APC) in the air and dust particle release (LPC) in the liquid. Many people think that jittery chipping is an intolerable problem of dust-free cloth. Actually, on the contrary, the jitter-removing chip is a physical property of the dust-free cloth itself, but it is only how high or low the chipping is. 2. The amount of ionization of the dust-free wiping cloth. Mainly check for highly active metal ions and non-metal ions. If the surface of the object you are wiping has a precise metal material, it is recommended that the precipitation of ions be an important inspection item because the active ions can easily destroy the surface of the precision metal through the battery reaction. 3. The amount of non-volatile matter (NVR) of the dust-free wipe in the solvent. The solvent is usually used, and the solvent is used for evaluation. The amount of the residue is usually tested by a sophisticated weighing device, but the user can also determine whether the residue of the lint-free cloth is within the required range by means of a test wiping or fogging. As an important cleaning tool in the dust-free workshop, the dust-free wiping cloth is very popular among customers, and the application is also very wide. Therefore, users should also follow the standard in purchasing, and it is not cheap, so that you can buy a high-quality dust-free cloth. Imitation microfiber dust-free cloth, high density According to the purification level, there are: Grade 10 dust-free cloth, 100-level dust-free cloth, 1000-level dust-free cloth, and 10,000-level dust-free cloth; According to the function, there are: nuclear industry dust-free cloth, radiation-proof dust-free cloth, photoelectric dust-free cloth, PCB dust-free cloth, anti-static dust-free cloth, conductive dust-free cloth, polished dust-free cloth. According to size and packaging: regular packaging is 9 inches, 6 inches, 4 inches, special specifications need to be customized.

1:The damage of static electricity to the electronics industry First, ESA electrostatic adsorption, it will cause serious pollution. We know that the IC production process requires a clean workshop or an ultra-clean workshop. However, few domestic manufacturers can achieve that there is no particle in the clean room. Now it is required that the particle size of dust particles is reduced from the original 0.3μm to the current 0.1μm, but if the particle size of the adsorbed dust particles is larger than the line width , It is easy to scrap the product. Second, ESD electrostatic discharge, it will cause device breakdown. Electrostatic discharge is the process of charge accumulation. When the charge accumulates to a certain level, a conductor close to it will cause electrostatic discharge. If a semiconductor device with a certain amount of static electricity is placed alone or loaded into a circuit module, it will be broken down immediately. After the device is affected by electrostatic discharge, there may not be immediate functional damage, but it will affect the reliability of the components. The losses caused by electrostatic discharge can reach billions of dollars a year. Third, EMI electronic interference, it will cause damage. Electrostatic discharge will radiate a lot of radio waves, and these radio waves have frequency, which will cause great interference to the surrounding microprocessors, such as chaotic program instructions, chaotic data, unknown error messages, etc. , And these problems are generally not taken seriously, but once a malfunction occurs, the harm it brings will be huge. Static electricity can cause harm to electronic devices, but it is controllable and can be eliminated. 2:Elimination and control of static electricity Static Electricity Elimination 1. Prevent the accumulation of static charge in places where static electricity may occur. That is to take certain measures to avoid or reduce the generation of electrostatic discharge. The method of generating and leaking can be used to eliminate the charge accumulation. 2. The existing charge accumulation should be quickly eliminated. When an insulating object is charged, the charge cannot flow and cannot leak. A static eliminator can be used to generate opposite ions to neutralize the static charge. When the charged object is a conductor, a simple ground leakage method is used to completely eliminate the charge. Static Electricity Control 1. Minimize static charge during the production process. Preventive measures should be taken in the process of material selection, equipment installation and operation management in the process flow to control the generation of static electricity and the accumulation of electric charges, restrain the electrostatic potential and discharge energy, and minimize the harm. 2. Electrostatic grounding is used to make the charge leak to the ground, and the method of increasing the conductance of the object is usually used to make the static electrici...

What is a clean room? A cleanroom (GMP cleanroom), in my mind, is a combination of engineering design, fabrication, finish and operational controls (control strategy) that are required to convert a “normal” room to a “clean room”. This blog will attempt to explain the necessary characteristics of a regulated company clean room not producing potent chemicals or active or hazardous biologicals. If there are significant containment requirements, the requirements would be outside the scope of a “simplistic” blog like this. In a pharmaceutical sense, clean rooms are those rooms that meet the code of GMP requirements as defined in the sterile code of GMP, i.e. Annex 1 of both the EU and PIC/S Guides to GMP and other standards and guidance as required by local health authorities. So why do I need a clean room? There is no GMP requirement in the EU and PIC/S (i.e. TGA) GMP guidance’s for the manufacture of non-sterile medicinal products in a “clean room”, but we do use clean areas that are effectively ventilated with filtered air where the products or open, clean containers are exposed. On the other hand, clean rooms are mandatory for the manufacture of sterile medicinal products, as defined in Annex 1 of the EU and PIC/S GMPs. This Annex defines many additional requirements besides the airborne particulate concentration limits used to classify clean rooms. In a nutshell, if you manufacture a non-sterile medicinal product, you should be very careful about classifying or grading your clean areas, for example, classifying a room as “Grade D”. Whilst not a code requirement, many regulators, like the Australian TGA will expect you to fully comply with all of the requirements for a Grade D room as defined in Annex 1, even if it’s not a GMP code requirement. Therefore, if you have classified the room as Grade D, you will need to live with the consequences and costs of maintaining this level of cleanroom cleanliness during operation. What type of clean room do I need? If you are a manufacturer of non-sterile medicinal products, you should define your own cleanroom/area standards using national and international standards. Usually manufacturers will define an airborne particulate concentration standard class such as ISO 14644-1 ISO 8 (at rest), outline gowning and a pressure cascade regime, defining a “clean corridor” design or a “dirty corridor” design. If you are a manufacturer of sterile medicinal products, you must follow the EU or PIC/S GMPs, namely Annex 1.

· Polypropylene/Cellulose – High absorbency, durable, resistant to acids and other chemicals. · Blue Polypropylene/Cellulose – Visual inspection background, general purpose cleaning. · Polyester/Lyocell – Cleanest nonwoven, high absorbency, exceptionally soft, works well with IPA and other solvents. · Bonded Polypropylene/Cellulose – Economical, high absorbency, cellulose core for excellent wicking of solvents. · Meltblown Bonded Polypropylene – Multi layer, high durability and sorbent, engineered for use with acids, certified for contact with food. · Hydroentangled Rayon/Polyester – Highly absorbent with all liquids, durable, soft, non-scratching. · Spunlaced Polyester – Very clean, absorbent with solvents, soft non-scratching, strong wet or dry. · Cotton – 100% Biodegradable, low ionic contamination, heat resistant, high absorbency, no binders. · Rolls of Poly/Cellulose nonwoven wipes – special applications requiring roll materials. Dry low lint wipes are made of all-purpose industrial nonwoven material. Durable and low linting for use outside of the cleanroom, a controlled environment or lab area.

Dust-free wipe cloth in many industries can be used, dust-free cloth texture soft and delicate, supple, easy to absorb water absorption of the three major effects, so that dust-free products in the field of production application is quite extensive, now more and more friends for this product is very popular. A lot of procurement on how to choose the right dust-free cloth, but also headaches, dust-free cloth type is a lot, but when you understand, in fact, not that complex. General production of dust-free workshop suitable for the use of larger size of the wipe, in order to make dust pollution removal more thoroughly, to protect the environment of clean production Workshop more comfortable. For the higher surface cleanliness requirements of the products, it is necessary to use a clean clean dust-free cleaning products, in order to achieve the purpose of purifying dust. Dust-free fabric of the material structure is more complex, applicable to clean the use of dust-free workshop, according to the actual production of different workshops, choose the right dust-free cloth, so that the effect reached. And one thing to note is that the purchase of dust-free cloth attention, you put these points get to the words, then you will certainly choose to suit your dust-free cloth. Dust-free cloth is a dust-free workshop special cleaning supplies, with a strong cleaning and decontamination capacity, will not produce two of the workshop pollution and reverse pollution, can withstand the erosion of various solutions, but also suitable for laboratory experiments to ensure the authenticity and effectiveness of the test, how to choose the right dust-free cloth, now should have known. Ultra low dust is the basis for judging the quality of dust-free cloth, such a dust-free cloth is suitable for use in high-precision dust-free workshop. Especially High-tech industries, electronic chips, medical industry, high-end laboratories and other places.

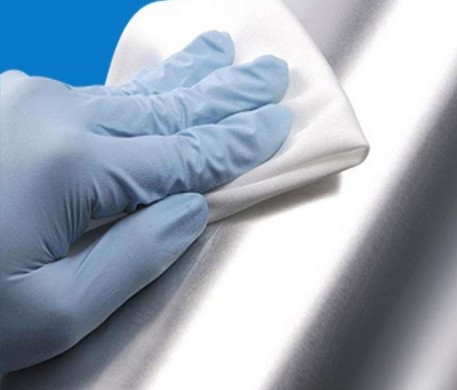

Correct use of dust-free cloth: 1. Wear clean gloves and masks when using and unpacking 2. When wiping, wrap the four sides of the clean cloth inside, and do not use the edge of the clean cloth to touch the surface of the wipe 3. The clean cloth can be wiped with solvent or directly wiped 4. The dust-free cloth should be kept flat and not rubbed during use. When moving and wiping, try to make the fibers of the cloth in full contact with the wiping surface. Make sure to wipe in the same direction, and do not wipe back and forth repeatedly. 5. When using the high-end dust-free cloth, the inner packaging bag must be opened in a clean environment, and the packaging bag should be cleaned (especially the opening) before unpacking. Cleaning of the dust-free cloth: 1. Wash with washing machine and detergent or hand wash with warm water and detergent. 2. Rinse thoroughly with clean water after washing. 3. Using bleach will shorten the lifespan of microfiber cleaning wipes. 4. Do not use softener. Softeners leave a film on the surface of the microfibers. Will seriously affect the wiping effect. 5. When washing or drying in a washing machine with other clothes, pay attention, because the microfiber fabric will absorb the surface of the soft clothes, which will affect the use effect. Air dry or dry on medium-low temperature. Do not iron and expose to the sun. From its English name, we can see the two main characteristics of clean paper: one is that the raw material is wood pulp fiber; the other is the use of airlaid technology. The production process of non-woven fabrics is mainly two processes of network formation and reinforcement. The production of dry-laid nonwovens mainly adopts two methods: chemical bonding and thermal bonding. According to the different reinforcement processes, its raw materials and uses are different, which are introduced separately below. 1. Chemical bonding method The chemical bonding method uses 100% wood pulp fiber (fluff pulp) as raw material, and after the fibers opened into single fibers are air-laid, the water-soluble adhesive is sprayed onto the fiber web by spraying method. The surface is then baked and consolidated into cloth. The main uses of the products are industrial wipes, feminine hygiene products, baby wipes, tablecloths, wet face towels and cooking cloths. 2. Dust-free cloth thermal bonding method The thermal bonding method is to mix hot-melt fibers into the fluff pulp fibers, and the mixing ratio is generally not less than 15%. The fibers melt to consolidate the web into cloth. Thermal bonding non-woven fabrics have better bulkiness and hygroscopicity because they do not contain chemical adhesives. They are mainly used as absorbent cores of high-absorbent sanitary products, thin feminine sanitary napkins, etc. For this purpose, some production lines are equipped with superabsorbent resin (SAP) powder application devices. Due to the addition of polymer water-absorbing resin, the water can be turned into a solid aft...

SMT, also called SMT automatic wiping paper, SMT roller wiping paper, SMT dust-free roll paper, SMT wiping roll paper, etc. Commonly used steel mesh paper is made of natural wood pulp and polyester fiber, and processed by unique spunlace method, forming a unique wood pulp/polyester double-layer structure. Especially, it is the best product for removing SMT steel mesh and excess solder paste and red glue on circuit board, and keeping the circuit board spotless. It can greatly improve the production efficiency and product quality. In order to improve the working efficiency of customers, save expenses and effectively control the consumption. SMT steel mesh wiping paper can be divided into two types: plain paper and grid paper. The weight is 56-68 g/m2, the thickness is 0.3-0.35 mm, and the width is 23-200cm. There are two kinds of lining pipes: paper pipe and plastic pipe. There are slots or no slots at both ends of pipes used by different printing machines. Generally, it can be used for all automatic printing machines such as MPM, DEK, KME, YAMAHA, MINAMI, JUKI, EKRA, PANASERT, FUJI and SANYO. The width and length of SMT steel mesh wiping paper, and the diameter and length of inner liner pipe are determined by the actual printed product size and printing model. The following are the main properties of SMT steel mesh wiping paper: 1. Strong toughness and durability. SMT steel mesh wiping paper has a strong adsorption capacity on water and oil stains, which can quickly and efficiently adsorb the water and oil stains on objects, thus achieving the characteristics of strong cleaning and deep water and oil removal. In addition, it has inherent softness, dust-free and anti-static effects, and the dust will not fall off to make it soft and delicate when wiping dirt, so that people can use it freely, especially in the dry environment in winter, it will not produce static electricity, and will not cause conductive electric shock and other injuries. 2. The texture is soft and harmless. This kind of wiping paper has the characteristics of soft texture, steel but not hard. Whatever the body is soft or hard, it will not cause scratches or leave scratches and other damages, thus truly achieving the advanced effect of no harm to the body. Thoroughly achieved the value for money, the results of what can be achieved. 3. Strong liquid absorption ability and strong decontamination. SMT steel mesh wiping paper has unimaginable liquid adsorption capacity, and has strong adsorption capacity for all kinds of liquids, which can achieve deep cleaning effect with one action. It can efficiently adsorb ordinary stains, intractable stains and high-permeability stains on the surface, so that all kinds of dirty things can be collected and cleaned cleanly and clearly. Moreover, the wiping paper does not use any chemical reagents, thus achieving zero pollution, environmental protection, safety and hygiene. 4. Wide application of clean room. As we all know, especially in the electr...

The difference between non-woven fabric and clean cloth Non-woven fabrics, also known as non-woven fabrics, are environmentally friendly materials with the characteristics of water repellency, breathability, flexibility, non-combustion support, and rich colors. If the non-woven fabric is naturally decomposed outdoors, its life span is only 90 days, and it will decompose within 5 years if placed indoors. It directly utilizes polymer chips, short fibers or filaments to form new fiber products with soft, breathable and planar structures through various web forming methods and consolidation techniques. It has environmental protection properties that plastic products do not have, and its natural degradation time is much lower than that of plastic bags. The dust-free cloth is double-woven from 100% polyester fiber. The surface is soft, easy to wipe sensitive surfaces, and the fibers will not be rubbed off. It has good water absorption and cleaning efficiency. The cleaning and packaging of the products are all done in the ultra-clean workshop. The optional edge sealing of the clean cloth generally includes: cold cutting, laser edge sealing, and ultrasonic edge sealing. Microfiber clean cloth generally uses laser, ultrasonic perfect edge clean cloth, clean wipe, microfiber clean cloth, microfiber wipe using 100% continuous polyester fiber double woven cloth The surface is soft and can be dried Wipe sensitive surfaces, with low dust generation and no defibrillation due to friction, good water absorption and cleaning efficiency. Especially suitable for dust-free purification workshop.

Categories

New Products

Cleanroom Wipers For Screen Cleaning Fiber Lint Free Cleanroom Wipes Dust Free Read More

Polyester Spunlace Double Knit Nonwoven Cleanroom Wipes Read More

Polyester Nylon Knitted Microfibre / Microdenier Wiper Read More

Direct Manufacturer Factory Selling Nonwoven Wiper Rolls Industrial Wiper Rolls Read More

Copyright © 2024 Nanan Jiedao Electronic Material Co.,Ltd.. All Rights Reserved. Powered by

IPv6 network supported