A few years ago, the domestic market did not have a wipe at all. The water, oil and dust on the production line were mostly wiped with rags. With the development of the economy, the country is increasingly demanding environmental protection, and the requirements for the hygiene of the production line workers and the maintenance of the machines are getting higher and higher, and the wipes are born. Turning over the development process of the entire wiping cloth, the products are getting more and more fine, the quality requirements are getting higher and higher, and the outer packaging is more and more beautiful. For example, there is a sponge wiper. This material is soft and absorbs a lot of water, but it is still bad for stubborn stains, and a wiping member made of organic fiber is used. He has a high resistance to friction, and the fiber's ability to resist friction can also increase his wiping effect by covering it with a synthetic resin containing abrasive particles. The construction of such microfiber cleanroom wipers fibers is usually made up of a three-dimensional network. The fibers are bonded to each other at their intersection. Bonding can be accomplished by direct fiber bonding or by adhesive. This type of wipe paper is available on the market.

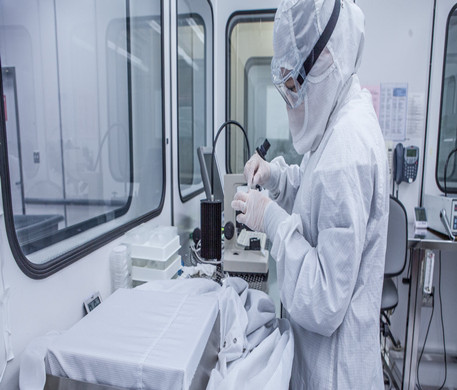

Abbie (Carlstein) Gregg ’74 remembers giving up on wearing lab gloves during her undergraduate research at MIT. There weren’t any small enough to fit her, at a time when undergraduate men outnumbered women on campus 15 to 1. Even so, it was the first time she’d met other women interested in engineering and technology—and she quickly found a home in the Metallurgy Department (now Materials Science and Engineering). Four decades later, Gregg has made a career designing clean rooms and labs for semiconductor manufacturing and research all over the world.(How to use polyester cleanroom wipers in a clean room.) At MIT, Gregg was drawn to semiconductors. For her thesis, she and collaborators sent semiconductor crystals into space on NASA’s Skylab to test the theory that gravity causes non-uniformities in crystal growth, which they predicted would lead to defects in circuit function as chips became more complex. “We brought the crystals back to Earth and we measured them, and sure enough, they were completely uniform,” she recalls; meanwhile, those they’d grown on Earth “had all these non-uniformities.” Gregg would later revisit this work as a “thought experiment” for an aerospace company exploring device fabrication in space. After MIT, Gregg worked at Fairchild Semiconductor on improving its manufacturing. Through discussions with workers, “I became interested in the built environment, and in optimizing both the human factors and the product yield,” she says. Gregg began designing semiconductor manufacturing plants, spending about 10 years as a “startup junkie” at different companies before founding Abbie Gregg, Inc. The firm completed some 850 projects, primarily for university, industry, and government labs, before it was bought in 2019 by AM Technical Solutions (where Gregg is now chief technology officer). She strives to create spaces that are safe, functional, and aesthetically pleasing, with plenty of windows and natural light. “People don’t put windows in clean rooms because they say ‘We don’t want to look at an industrial scene,’” Gregg says. “But if a clean room doesn’t look beautiful, there’s something wrong with it; it’s poorly planned or it isn’t maintained.” One of Gregg’s favorite projects brought her back to where she started: MIT. She did the initial planning and design for the clean rooms and labs in MIT.nano, MIT’s new home for nanotech research. Shortly after it opened, she visited campus for her 45th reunion in 2019. “I stopped and watched the new graduates peeking into that building and showing their parents,” she recalls. “That was the most amazing feeling. That’s my legacy.”

The last year and a half has put wipes, especially disinfecting wipes, in the forefront, as consumers, businesses, institutions and other facilities clamored for them at the height of the Covid-19 pandemic to keep surfaces sanitized. Now that the dust has settled as we near the end of 2021, and the supply of wipes has opened up, it’s no surprise that demand has begun to level off. “In 2020, a lot of facilities and businesses were stocking up on wipes, especially disinfecting wipes, and I think the fear of running out was driving a lot of that,” says Laura Mahecha, industry manager at Kline. “Because they stocked up a lot last year, there’s been some flatness in the market because (companies) are still using the stockpiles that they amassed last year. But, with kids going back to school, people going back to work, and with the delta variant of Covid-19, plus regular cold and flu season, I think there is upswing potential in wipes for surfaces and hands going into the fall.” Wipes have surely become more ubiquitous over the last year and a half. They’re not only being used by cleaning staff at facilities; they’re being made available in public areas for consumer use, like hand sanitizers have been, Mahecha explains. “Office buildings now have wipes that can be used to wipe down the buttons on an elevator, or in a hotel lobby they now have wipes; wipes are in places where they were really never stocked before.” PDI, a manufacturer of wipes that specializes in infection prevention, expects cleaning practices and behaviors that were so ingrained in everyone during the height of the pandemic, to remain a high importance as variants emerge and we move into this year’s flu season. “Surface and hand disinfection are two of the easiest practices we can control to help reduce the spread of viral and bacterial pathogens,” says Ben Dolcimascolo, PDI director of marketing, Environment of Care. “Unsurprisingly, the frequency in which people disinfected both surfaces and hands during the pandemic drastically increased. Across all industries, surface and hand disinfection was at the core of the enhanced safety precautions put in place. Most public establishments including food stores, shopping malls and restaurants tried to do their part in reducing the spread of Covid-19 by supplying customers with disinfectant and hand hygiene products at entrances. Hospitals also put new enhanced disinfection policies in place, increasing how often they disinfected surfaces and making sure the products they used were effective against SARS-CoV-2.” Jenny Turner, marketing director for Industry for Essity’s professional hygiene business, which makes wipers under the Tork brand, says the I&I wipes market has been put under demand pressure through the Covid pandemic, steering more surface cleaning and hygiene through reinforced protocols at end users. “The demands have been even stronger in hygiene, disinfection, sanitizing wiper solutions securing employee safety,” she adds. ...

China has extended power restrictions to at least 20 provinces and regions as it struggles to cope with the power shortage in its north-eastern region. The areas affected by the most recent restrictions together account for more than 66% of the country’s gross domestic product. The power cuts are reportedly causing power supply discrepancies, with the situation expected to further inflate global supply chains. Chinese state media reported that Heilongjiang, Jilin and Liaoning are among the north-eastern provinces most affected by the power shortages. Two factors have contributed to the ongoing ‘power crunch’ situation in the country. A rise in coal prices has caused power generators to trim their production capacity despite an increase in power demand. In addition, some provinces have had to halt their electricity supplies to meet emission and energy intensity goals. As a result, millions of homes in the country are facing a blackout situation, with factories closing their operations. What has the impact been on China's economy? Official figures have shown that in September 2021, Chinese factory activity shrunk to the lowest it had been since February 2020, when coronavirus lockdowns crippled the economy. Concerns over the power cuts have contributed to global investment banks cutting their forecasts for the country's economic growth. Goldman Sachs has estimated that as much as 44% of the country's industrial activity has been affected by power shortages. It now expects the world's second largest economy to expand by 7.8% this year, down from its previous prediction of 8.2%. Globally, the outages could affect supply chains, especially towards the end-of-the-year shopping season. Since economies have reopened, retailers around the world have already been facing widespread disruption amid a surge in demand for imports. It hasn't made a big influence to the Fujian factories,our factory had been told to stop the production for two weeks.But still of that,we lose a big deal of polyester clean room wipers.

Masks are essential personal protection equipment (PPE) for proper cleanroom protocols. But are two masks better than one? A new study published by The Centers for Disease Control and Prevention (CDC) shows that double masking can be more effective at reducing aerosol exposure. In light of these findings, the CDC now offers protocols for double masking. While there are clear benefits, double masking is not always the best practice in every situation. It’s unlikely that you’ll find double masking protocols in any cleanroom management plan. Here’s what you need to know about double masking and your cleanroom. What the CDC says about double masking When it comes to protection, it’s not really about wearing multiple masks. It’s about wearing multiple layers. In a study published in February 2021, researchers found that when compared to either a cloth mask or a surgical mask alone, wearing a double mask was more effective at reducing aerosol exposure.1 The CDC recommends two ways to increase your layers of protection: Choose a mask with multiple layers of fabric. Wear a surgical mask underneath a cloth mask (double masking). The CDC cautions against combining two disposable masks or combining an N95 mask with any other mask. These methods will compromise the fit of your mask.2 Quality over quantity A quality fit is the most crucial component of effective mask wearing. If double masking compromises the fit, then it defeats the purpose. The CDC provides these tips to ensure that your mask fits properly: Your mask should completely cover your nose and mouth. Make sure your mask fits snugly against the side of your face and that there are no gaps. Choose masks with nose wires. Bend the metal strip along the tip to conform to your face. This prevents air from leaking through the top of your mask. Wear a mask fitter or brace. When worn over a cloth or surgical mask, this device will prevent air leakage from around the edges of the mask. People with facial hair are encouraged to trim or shave their beard, use a mask fitter, or double mask.3 Proper mask use in a cleanroom Neither The Food and Drug Administration (FDA) nor the CDC set guidelines for cleanroom equipment. The FDA only regulates PPE like surgical masks and N95 masks when they are marketed as medical devices.4 If your cleanroom’s purpose is outside of the medical field, you are likely following International Organization for Standardization (ISO) or Current Good Manufacturing Practice (CGMP) recommendations for your equipment. Cleanroom masks are multi-layered and made from materials such as polypropylene that will not shed lint or fibres. The goal is to limit the amount of particles that could contaminate the air or surfaces in the cleanroom. Some cleanroom management plans require face masks that are “cleanroom rated” based on the amount of particles that flake off of the mask. The ISO classification of the cleanroom will determine just how clean the mask needs to be. The only CDC protocol for m...

The financial status of all the business sectors has been impacted since the outbreak of COVID-19 epidemic along with the lockdowns in several countries across the globe. The same can be reflected on the private healthcare sector which was majorly impacted due to the pandemic as the lockdowns have disrupted the production, supply chain, and the distribution of medical supplies across the globe. The number of footfalls in dispensaries and clinics has dropped by over 70% due to the social distancing measures which has resulted in reduction in surgical procedures, hence impacting negatively on growth of the market. The demand for gloves and PPE kits has increased which has led to increase in production of these equipment, thus elevating the growth of the market. Overview This market involves creating a clean environment in a space or room by minimizing the contaminations in the air such as particulates, dust, airborne microbes, and viruses with the help of consumables. The consumables are the safety and precaution equipment such as PPE kits, gloves, face-masks, googles, etc. Generally, these consumables are used in medical, industrial and in scientific research work. Furthermore, the consumables find their applications in the pharmaceutical and healthcare sector. The consumables for the cleanroom help in maintaining a controlled and healthy environment along with the efficient and safe workflow of healthcare workers and professionals. Drivers The ongoing COVID-19 pandemic is expected to further propel growth of the global cleanroom consumables market over the forecast period. For instance, in March 2020, the World Health Organization (WHO) had estimated the requirement of 89 million masks, 76 million gloves, and 1.6 million googles for combating COVID-19 epidemic. Accelerated research work across the globe to develop new vaccines and drugs for treatment of various diseases is expected to boost the growth of global cleanroom consumable market during the forecast period. In April 2020, the Congressional Research Service reported that the global expenditures on R&D has tripled from US$ 676 billion to US$ 2.0 trillion in last 18 years. By Product Type: Cleanroom Apparels: Coveralls, Frocks, Shoe Covers, Bouffants, Sleeves, Pants, Face Masks, Hoods. Cleaning Products: Cleanroom Mops, Buckets, Wringers, Cleaning Chemicals, Others (Squeegees and Validation Swabs). Cleanroom Stationery: Papers, Notebooks, Adhesive Pads, Binders, Others (Clipboards and Labels). Cleanroom Wipers: Dry, Wet(like nonwoven cleanroom wipers,polyester wipers etc.). Gloves Adhesive Mats By End User: Hospitals and Clinics, Research Laboratories, Pharmaceutical Industry, Biotechnological Industry, Medical Device Industry, Electronic Industry, Others.

An ISO 14644-1 classified cleanroom is a room or contained environment where it is crucial to keep particle counts low. Typically, these particles are dust, airborne microbes, aerosol particles, and chemical vapors. Beyond particle counts, cleanrooms often have controls for a number of other parameters like pressure, temperature, and humidity. Additionally, to be considered a cleanroom, the space needs High-Efficiency Particulate Air (HEPA) filters to remove particles from the air. ISO 14644-1 Cleanrooms are classified from ISO 1 to ISO 9. Each cleanroom class is denoted by a maximum concentration of particles per cubic meter or cubic foot of air. ISO 8 is the second lowest cleanroom classification. ISO 8 Cleanroom Standards The allowed particle counts for an ISO 8 cleanroom depend on the referenced standard and its measurements. According to US Federal Standard 209E, ISO 8 cleanrooms are also known as Class 100,000 cleanrooms. ISO 14644-1 replaced the federal standard and states that an ISO 8 cleanroom needs less than 3,520,000 of ≥ 0.5 micron sized particles per cubic meter of air. Only particles 0.5 microns or larger are measured in an ISO 8 cleanroom. This is done because the concentration of smaller particle sizes is too high. ISO 8 Protective Requirements and Design Considerations Designing a cleanroom requires taking additional regulatory standards and requirements into account based on industry and application. However, there are several general requirements and environmental parameters to consider for an ISO 8 cleanroom. For an ISO 8 Cleanroom, these include: HEPA filtration Air Changes per Hour (ACH) Air pressure Temperature and humidity Amount of personnel working in the space Static control Lighting Noise levels Since an ISO 8 cleanroom is focused on measuring particles 0.5 microns or larger, the HEPA filtration system needs to be 99.97% efficient and a minimum of 20 air changes per hour is recommended. The final filtration of air occurs where the air enters the cleanroom. Additionally, it is most common for ISO 8 cleanrooms to employ non-unidirectional or mixed air flow patterns with low wall air returns. Common ISO 8 Applications A wide variety of industries and applications have cleanrooms. Some of the most common with ISO 8 cleanrooms include: Medical device manufacturing Pharmaceutical manufacturing and compounding Semiconductor manufacturing Electronics manufacturing Frequently Asked Questions on ISO 8 What is the difference between ISO 7 and ISO 8? The two main differences between ISO 7 and ISO 8 cleanrooms are particle count and ACH requirements, which set them apart for differing applications. An ISO 7 cleanroom must have 352,000 particles ≥ 0.5 microns per cubic meter and 60 ACH per hour as opposed to ISO 8’s 3,520,000 particles and 20 ACH. When is a cleanroom required? A cleanroom can be used for a number of industries and applications. They are required for spaces where cleanliness and sterility are crucial. For context, a...

No matter what kind of controlled environment and industry you’re working within, maintaining a safe and productive cleanroom is absolutely essential to your daily operations — and even reputation. Getting the right HEPA air filter, having a laminar airflow hood, and even making sure that employee apparel and cleaning supplies don’t contaminate the environment can all help to keep cleanroom temperature and humidity levels consistent. But what are cleanroom guidelines and regulations regarding temperature and humidity levels in the first place? What’s more, why are they so important within the cleanroom environment? Keep on reading this post to find out. Understanding Cleanroom Humidity Levels Common cleanroom guidelines state that Relative Humidity (RH) levels in cleanrooms should remain between 30-40% RH year-round. Usually, temperatures below 21 degrees Celsius (70 degrees Fahrenheit) have a +/- 2% RH band. Even though cleanrooms are pressurized, you’ll still need to take extra care to ensure that humidity levels in the cleanroom don’t fluctuate. High humidity levels can cause a host of cleanroom problems, such as the growth of bacteria, product degradation/damage, corrosion, and static electricity. Static electricity directly interferes with the movement of particles inside of the cleanroom, which can cause serious production problems. High humidity levels can cause solvents to evaporate and water to cool and condense moisture. Thus, compromising both process control and quality. In a pharmaceutical environment, high humidity levels in the cleanroom can lead to clogs in the tablet dies due to powder inconsistency. Plus, constantly fluctuating humidity levels make cleanroom employees uncomfortable. These issues can lead to costly mistakes, low-quality products, and may even cause serious production delays. Looking at Cleanroom Temperature Now that you have a better understanding of cleanroom guidelines relating to humidity levels, let’s take a look at standards for cleanroom temperature. In general, the temperature of a cleanroom should be 21 degrees Celsius, or 69.8 degrees Fahrenheit. Usually, a fluctuation of 2 degrees celsius is permissible. Like humidity levels, it’s important to maintain a standard temperature in cleanrooms to keep employees comfortable. The reason why their comfort matters is even more interesting. When cleanroom cleaning staff or technicians shiver or even sweat, they release a higher amount of particles into your cleanroom. This, potentially contaminating the environment and compromising production standards. Where Can You Get Top Cleanroom Supplies? As you’ve learned from this post, even small fluctuations in cleanroom temperature and humidity levels can cause serious issues for cleanroom staff and production as a whole. You need to be certain that the cleanroom cleaning supplies you provide to your clients will help them to maintain industry standards for temperature and humidity. Getting the right products and suppl...

Categories

New Products

Cleanroom Wipers For Screen Cleaning Fiber Lint Free Cleanroom Wipes Dust Free Read More

Polyester Spunlace Double Knit Nonwoven Cleanroom Wipes Read More

Polyester Nylon Knitted Microfibre / Microdenier Wiper Read More

Direct Manufacturer Factory Selling Nonwoven Wiper Rolls Industrial Wiper Rolls Read More

Copyright © 2024 Nanan Jiedao Electronic Material Co.,Ltd.. All Rights Reserved. Powered by

IPv6 network supported