We,Jiedao,established in 2013,rooted from a small plant in 1999, devoted in the development and manufacturing of cleanroom and antistatic products.Our main products include Class 100-10,000 cleanroom wiper,cleaning swab,SMT stencil roll,sticky mat,ESD mat,ESD garment,ESD SMT magazine rack, and other ESD products.Our customers are involved in various sectors:Micro electronics, Automotive ,Electronics, Medical, Clean Room and Antiszone.Our promise:Jiedao Product,Well Produced.Our conception:Customer Oriented,Pursuing Better Quality,Striving for Ennovation.Our vision:To be One-stop Business Partner for Cleanroom and ESD Products.

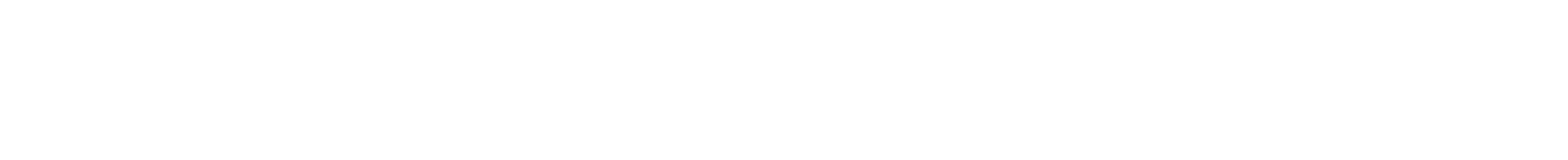

Polyester wipes are 100% virgin, continuous-filament polyester in a double-knit, no-run interlock design with a laser cut, sealed edge. Recommended for use in cleanroom critical environments and a wide variety of applications including cleaning medical devices, electronics displays, instrument panels, semiconductors, and microelectronics products.

Polyester wipes are 100% virgin, continuous-filament polyester in a double-knit, no-run interlock design with a laser cut, sealed edge. Recommended for use in cleanroom critical environments and a wide variety of applications including cleaning medical devices, electronics displays, instrument panels, semiconductors, and microelectronics products.

Read More >>

Microfiber is a blend of polyester and knitted nylon. Microfiber increases the surface area, which provides superior wiping efficiency and absorptive performance. The silky texture of microfiber is designed for delicate/scratch sensitive surfaces.

Microfiber is a blend of polyester and knitted nylon. Microfiber increases the surface area, which provides superior wiping efficiency and absorptive performance. The silky texture of microfiber is designed for delicate/scratch sensitive surfaces.

Read More >>

Sub superfine dust-free wiper is cut by laser or ultrasonic and seal edge in class 10-100 clean room after ultrapure water washing, and then vacuumize it. Extreme soft material, without any damage to the surface, even in high-precision fields, such as coated lens, a large scale integrated circuit production process can also be assured that use. Excellent and high-density weaving structure make the specific surface area for the per gram of microfiber cleaning cloth reaches 200m2, dust absorption rapidly increase several times, only need to wipe slightly then will be able to completely clean the surface. Ultra-fine fibers, the excellent capillary effect, fast dry as it was one of the notable characteristics. High-strength synthetic fiber filament, not easy to break, the fibers don’t easily fall off from a cleanroom cloth, non-polluting in the clean region. Laser cut sealed edge and ultrasonic cut sealed edge have unique cut and melt effect, it’s a thorough solution to dust generate phenomenon on the edge, it also largely improves the product quality, is the most advanced Cut sealed edge way, suitable for class 10-100 clean room.

Sub superfine dust-free wiper is cut by laser or ultrasonic and seal edge in class 10-100 clean room after ultrapure water washing, and then vacuumize it. Extreme soft material, without any damage to the surface, even in high-precision fields, such as coated lens, a large scale integrated circuit production process can also be assured that use. Excellent and high-density weaving structure make the specific surface area for the per gram of microfiber cleaning cloth reaches 200m2, dust absorption rapidly increase several times, only need to wipe slightly then will be able to completely clean the surface. Ultra-fine fibers, the excellent capillary effect, fast dry as it was one of the notable characteristics. High-strength synthetic fiber filament, not easy to break, the fibers don’t easily fall off from a cleanroom cloth, non-polluting in the clean region. Laser cut sealed edge and ultrasonic cut sealed edge have unique cut and melt effect, it’s a thorough solution to dust generate phenomenon on the edge, it also largely improves the product quality, is the most advanced Cut sealed edge way, suitable for class 10-100 clean room.

Read More >>

These general-purpose Spunlace non-woven wipes are constructed from a hydroentangled, non-woven blend of 55% cellulose and 45% polyester. This composite substrate has the highly absorbent properties of a natural fiber with the cleanliness and strength of a synthetic yarn. Recommended for use in cleanroom critical environments such as research labs, hospitals, and electronics manufacturers.

These general-purpose Spunlace non-woven wipes are constructed from a hydroentangled, non-woven blend of 55% cellulose and 45% polyester. This composite substrate has the highly absorbent properties of a natural fiber with the cleanliness and strength of a synthetic yarn. Recommended for use in cleanroom critical environments such as research labs, hospitals, and electronics manufacturers.

Read More >>

Stencil Wiping Rolls are used to remove residual solder paste from the bottom side of PC Board stencils. Using Stencil Wiping Rolls prevents smearing, bridging, and solder balls caused by normal printing of solder paste onto PC Boards. We manufacturer Stencil rolls in a wide range of sizes to fit popular printer models including; DEK machines, Speedline machines, MPM machines, EKRA machines, Panasonic machines, SMTech machines, and Yamaha machines.

Stencil Wiping Rolls are used to remove residual solder paste from the bottom side of PC Board stencils. Using Stencil Wiping Rolls prevents smearing, bridging, and solder balls caused by normal printing of solder paste onto PC Boards. We manufacturer Stencil rolls in a wide range of sizes to fit popular printer models including; DEK machines, Speedline machines, MPM machines, EKRA machines, Panasonic machines, SMTech machines, and Yamaha machines.

Read More >>

Our nonwoven cleanroom wipers are made from cleanroom-manufactured durable synthetic fibers and absorbent substrate. Polyester cellulose wipers are excellent for cleaning a controlled environment because the polyester provides strength for chemical resistance and natural cellulose provides absorbency for effective spill control and general wiping purposes. Vacuum-sealed packaging ensures your cleanroom wipes arrive contamination free.

Our nonwoven cleanroom wipers are made from cleanroom-manufactured durable synthetic fibers and absorbent substrate. Polyester cellulose wipers are excellent for cleaning a controlled environment because the polyester provides strength for chemical resistance and natural cellulose provides absorbency for effective spill control and general wiping purposes. Vacuum-sealed packaging ensures your cleanroom wipes arrive contamination free.

Read More >>

Nitrile gloves have good anti-static properties, comfortable to wear, good sticker and flexible operation.

Nitrile gloves have good anti-static properties, comfortable to wear, good sticker and flexible operation.

Read More >>

About us

Factory

Honor

Jiedao Electronic Material Co., Ltd is established in 2013,rooted from a small plant in 1999, devoted in the development and manufacturing of cleanroom and antistatic products.Jiedao registered capital is RMB 50,000,000,at the same time it covers 16000 square meters area. Our main products include Class 100-10,000 cleanroom wipers,industrial wiper rolls,LCD wiper rolls,cleaning swabs,SMT stencil rolls,sticky mats,ESD mats,and other ESD products.And our customers are involved in various sectors:Micro electronics, Automotive ,Electronics, Medical, Clean Room and Antiszone,until now,we have different customer sources from all over the world.Our products have been exported to Europe, South America,Africa,the Middle East,Russia,Southeast Asia and other countries. Our promise:Jiedao Products,Well Produced,we will produce every product with our years of experenice and the world's advanced cleanroom cleaning equipments. After all,your satisfaction is our TOP mission!

We,Jiedao,established in 2013,rooted from a small plant in 1999, devoted in the development and manufacturing of cleanroom and antistatic products.Our main products include Class 100-10,000 cleanroom wiper,cleaning swab,SMT stencil roll,sticky mat,ESD mat,ESD garment,ESD SMT magazine rack, and other ESD products.Our customers are involved in various sectors:Micro electronics, Automotive ,Electronics, Medical, Clean Room and Antiszone.Our promise:Jiedao Product,Well Produced.Our conception:Customer Oriented,Pursuing Better Quality,Striving for Ennovation.Our vision:To be One-stop Business Partner for Cleanroom and ESD Products.

30000

30000

Construction Area

6

6

Global Distributors

10

10

Employee

1

1

Made in China light steel frame machine

Recent Blogs

Recent Blogs

We,Jiedao,established in 2013,rooted from a small plant in 1999, devoted in the development and manufacturing of cleanroom and antistatic products.Our main products include Class 100-10,000 cleanroom wiper,cleaning swab,SMT stencil roll,sticky mat,ESD mat,ESD garment,ESD SMT magazine rack, and other ESD products.Our customers are involved in various sectors:Micro electronics, Automotive ,Electronics, Medical, Clean Room and Antiszone.Our promise:Jiedao Product,Well Produced.Our conception:Customer Oriented,Pursuing Better Quality,Striving for Ennovation.Our vision:To be One-stop Business Partner for Cleanroom and ESD Products.

Copyright © 2024 Nanan Jiedao Electronic Material Co.,Ltd.. All Rights Reserved. Powered by

IPv6 network supported