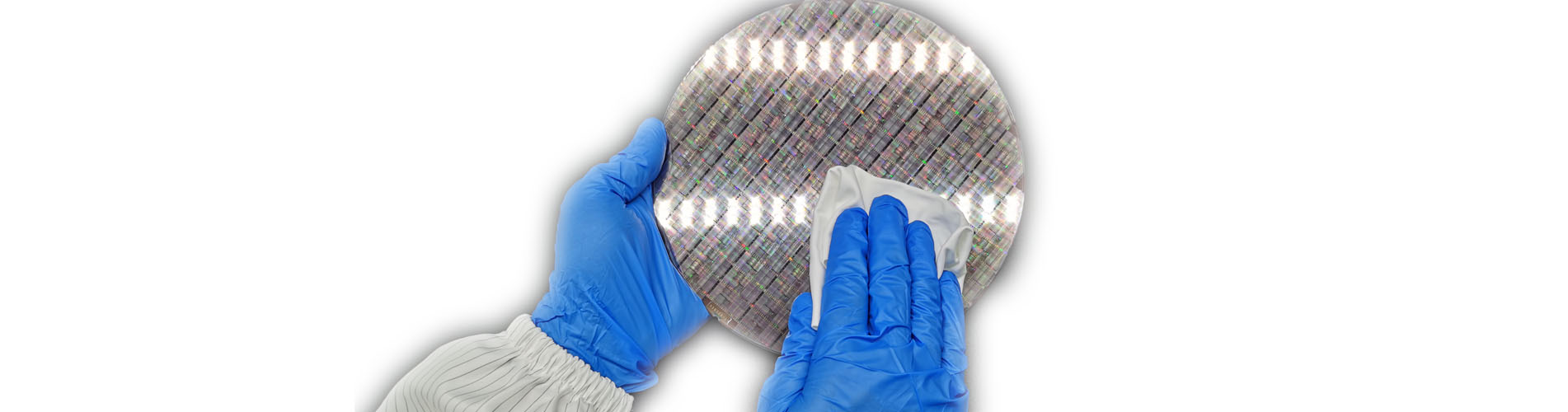

Cleanroom Wipes – Selecting The Correct Product Cleanroom wipes are a low lint cloth used in a clean room or controlled environment to wipe away surface contamination and spills. Common cleanroom contaminates would be solid particles, liquids and bio contaminants. Different types of clean room wipe material have been developed to offer absorbency, cleanliness, resistance to chemicals and abrasion resistance. What Types of Cleanroom Wipe Are Available? Basically, there are three types to consider: Woven Non-Woven Pre-Saturated There is also the consideration as to whether a wipe should be sterile or non-sterile. Woven Cleanroom Dry Wipes Polyester Cleanroom Wipes Polyester Cleanroom Wipes Dry knitted or woven polyester cleanroom wipes are the cleanest level of wipes. Most widely used in a Class 10 (ISO 4) and Class 100 (ISO 5) cleanrooms. The wipes are most often manufactured from 100% polyester. They are available in a variety of edge finishes. Advantages: Strong, will not tear, non-shedding Clean, low in particles, used in the most critical applications and critical clean rooms Soft, Non-Abrasive Can be Gamma Irradiated for sterility. Low microbiological endotoxin levels Highly Absorbent Types of Edges finish: Knife Cut Edge Laser Sealed Edge Ultrasonically Sealed Edge The highest specification wipes include either laser or ultrasonic edge sealing to reduce contamination. Non-Woven Cleanroom Wipes Cellulose Cleanroom Wipes Cellulose Cleanroom Wipes Dry non-woven cellulose cleanroom wipes are generally manufactured by two methods: Melt blown material is extruded and formed into a batting which is than thermally bonded. Another method has Hydroentangled fibers which has thousands of high pressure pin size jets that shoot water at the batting of blended fibers to form the material. This method uses no binders. Each fiber material has unique qualities making it suitable for different applications as a clean room wipe. Advantages: Economical High sorbency Strong Low linting Polypropylene/Cellulose – High absorbency, durable, resistant to acids and other chemicals, autoclavable Blue Polypropylene/Cellulose – Visual inspection background, general purpose cleaning Polyester/Lyocell – Cleanest nonwoven, high absorbency, exceptionally soft, works well with IPA and other solvents Bonded Polypropylene/Cellulose – Economical, high absorbency, cellulose core for excellent wicking of solvents Melt blown Bonded Polypropylene – Multi layer, high durability and sorbent, engineered for use with acids, certified for contact with food, Hydroentangled Rayon/Polyester – Highly absorbent with all liquids, durable, soft, nonscratching Spunlaced Polyester – Very clean, absorbent with solvents, soft non-scratching, strong wet or dry Sterile or Non-Sterile Cleanroom Wipes Sterile cleanroom wipes have been gamma irradiated to eliminate all living organisms. What is Gamma Irradiation? The treatment of medical devices by Gamma processing has been one of the principal methods ...

Clean Room Design For Manufacturing Flexibility Ensuring quality control while balancing long-term construction with short-term cutting, welding, or surface prep and spraying tasks is an ongoing logistical challenge. Navigating these cellular workflows is critical for aerospace OEMs, ship and boat manufacturers, and for operations conducting prototyping and R&D. How do you cost-effectively isolate manufacturing processes to keep damaging elements out and clean air around each workpiece?

What’s the Difference Between a Woven and Non-Woven Cleanroom Wipe? What's a Nonwoven Wipe? Nonwoven fabrics are broadly defined as a sheet or web structure bonded together by entangling fiber or filaments (or by perforating films) mechanically, thermally or chemically. Post-treatment and unique construction characteristics provide some potentially beneficial outcomes, such as a porosity that enables gas sterilization. Nonwoven wipes offer an economical choice, as the manufacturing process does not require laundering. Cellulose and synthetic blended hybrids provide additional absorbency for spill cleanup and removal of thick liquids. Generally, nonwoven wipes are used in cleanrooms no cleaner than ISO Class 6 or above. What's a Knit (Woven) Cleanroom Wipe? Woven wipes, also known as knitted wipes, assist contamination control in critical environments. Woven fabrics are the highest quality cleanroom wipes on the market today. Low levels of NVRs and superb particle removal is ideal for critical class environments. Unlike nonwoven fabrics, woven cleanroom fabrics are formed by knitting or looping monofilament, continuous polyesters or other synthetics. The outcome is cleanroom wiper with great tensile strength that will not shed. The lowest amount of linting and particulate generation yields compliance for ISO Class 3 and upwards. Microdenier or Microfiber Wipes for Cleanroom Applications? Microdenier, interchangeably used with microfiber, is constructed of synthetic yarn, typically a bi-component polyester-nylon polymer, or 100% polyester polymer. (View PDF) Microfibers absorb up to 99.4% of microorganisms found on the surface compared to only 30% for wipers containing cellulose. Therefore, microfiber is ideal for cleaning nano-sized particles, removing fingerprints from screen displays, applying or removing liquid, or wiping a wet surface dry. Problematically, the intense absorption characteristics render a material that is difficult to clean, and also retains many of the additives, ions, particulate and NVR acquired during the manufacturing process. Fragile bicomponent filament construction, such as 70% polyester and 30% nylon challenges particle control because it’s more susceptible to tearing, breaking, and shedding. For cleanroom use, a 100% polyester microfiber yarn ensures a cleaner more consistent wipe due to tightly knit filament structure which exceeds the cohesiveness of the previous generation of microfiber materials.

1

pagesCopyright © 2024 Nanan Jiedao Electronic Material Co.,Ltd.. All Rights Reserved. Powered by

IPv6 network supported