Cleanroom Requirements & Classifications

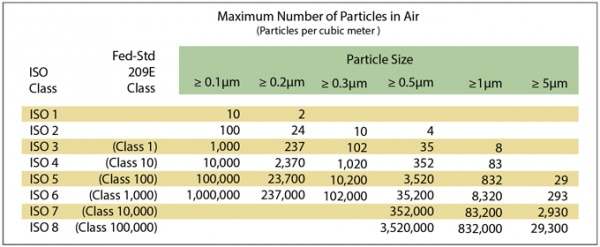

ISO classifications are based on international standards that regulate the acceptable cleanliness levels of each level of room. International Organization for Standardization SO 14644-1 provides the guidance for the acceptable air quality levels within the specific clean room ISO classes. Moreover, the cleanroom class is determined by the level of cleanliness the room complies with, according to the quantity and size of particles per volume of air.

What is an ISO Clean Room?

A cleanroom is a specially engineered and carefully designed enclosed area within a manufacturing or research facility. These rooms allow for precise control, monitoring, and maintenance of an internal environment. The numerous ISO classifications are specifically designed to regulate:

Temperature.

Humidity.

Airflow.

Filtration.

Pressure.

Each room requires a different level of cleanliness depending on the industry and application.

Cleanroom ISO Class Code Descriptions

Determining the correct cleanroom standards for a new product or business requires balancing many aspects. These can include process requirements, cost, performance and construction. Clean Air Products staff members work hands-on with you to review the basics of selection, and all applicable clean room industry requirements. Clean Air Products provides cleanrooms by ISO class, as well as additional cleanroom accessories to guarantee superior air quality and particle filtering. The following clean room classifications provide the recommended air changes per hour, per class of cleanroom:

ISO Class 1 - The “cleanest” cleanroom is ISO 1, used in industries such as life sciences and electronics that require nanotechnology or ultra-fine particulate processing. The recommended air changes per hour for an ISO class 1 clean room is 500-750, and the ceiling coverage should be 80–100%.

ISO Class 2 - 500-750 air changes per hour, with a ceiling coverage of 80-100%.

ISO Class 3 - 500-750 air changes per hour, with a ceiling coverage of 60-100%.

ISO Class 4 - 400-750 air changes per hour, with a ceiling coverage of 50-90%.

ISO Class 5 - 240-600 air changes per hour, with a ceiling coverage of 35-70%.

ISO Class 6 - 150-240 air changes per hour, with a ceiling coverage of 25-40%.

ISO Class 7 - 60-150 air changes per hour, with a ceiling coverage of 15-25%.

ISO Class 8 - 5-60 air changes per hour, with a ceiling coverage of 5-15%.

Cleanroom Industry Requirements & Classifications

Cleanroom requirements and standards are classified according to the number and size of particles permitted per volume of air in a specific amount of time. Clean Air Products engineers can provide guidelines and ISO class code descriptions for the class of cleanroom required for your specific application. Typically, businesses and organizations are aware of their cleanroom performance requirements because of customer, industry or government specifications. For example, government regulation USP 797 outlines specific requirements for pharmaceutical product manufacturing.

ISO cleanroom classifications are rated according to how much of a particulate of a specific size exists per cubic meter, within a given enclosure (see second chart). Clean room classifications are based on an eight class rating system, with an ISO class 1 cleanroom being rated the most particle-free and ISO class 8 allowing the most particles. This cleanroom standard rating system provides the necessary information to make an informed decision based on your product needs. Most clean rooms fall into the class 6,7, or 8 categories.

Previous :

What Makes a Cleanroom a Clean Room?Next :

Maintaining A Healthy EnvironmentCategories

New Blog

Copyright © 2024 Nanan Jiedao Electronic Material Co.,Ltd.. All Rights Reserved. Powered by

IPv6 network supported