How To Choose A Suitable Cleanroom Wiper?

Background

Today, many products are produced in a clean room environment, such as food, medicine, vaccines, semiconductor chips, and more. These environments must be regularly maintained to maintain the yield and integrity of the final product. And meet the quality requirements of the product itself.

A key activity in cleanroom maintenance is the wiping of environmental surfaces, equipment surfaces, and in some cases the final product itself, which requires the use of cleanroom-specific cleanroom wipes. Although dust-free wipes are a common cleaning product in clean rooms, how to choose a suitable wiper and what factors need to be considered when choosing is not a simple decision. The selection process is actually a professional solution.

And many companies do find that neglecting the cleaning/wiping job leads to a lot of rework, spending unnecessary money tracking down the source of contamination, and ultimately producing a defective product. Therefore, according to the industry and the actual production environment of the enterprise, choosing the appropriate cleaning plan and cleaning technology is of great benefit to production.

How to choose a suitable cleanroom wiper

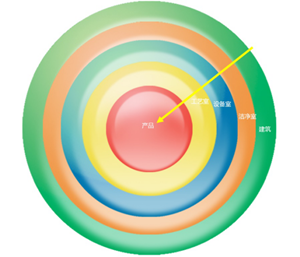

Those responsible for choosing wipes are constantly making a trade-off between cost and effectiveness. Hattori provides useful guidance for assessing contamination levels in semiconductor production equipment. If buildings, cleanrooms, equipment and process rooms are viewed as concentric circles of diameter from largest to smallest around the bull's-eye - the wafer - then more and more effort should be expended in approaching the bull's-eye to reduce pollution levels. This means that it is necessary to use the cleanest consumables on the production line.

Spunlaced paper made from polyester and wood cellulose may be a very suitable material for changing room cleaning, but for critical areas such as the interior critical production areas of semiconductor production lines or aseptic filling areas of pharmaceutical plants In terms of cleaning, it will cause greater pollution. In these areas, laser- or ultrasonic-edged, and washed knitted polyester fabrics may be the best choice for cleaning operations.

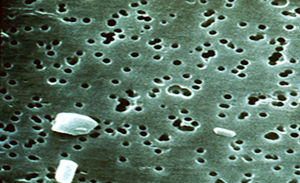

Polyester wiper particles magnified 5000 times

Cooper suggests that the 4Cs—cleanliness, performance, chemical compatibility, and cost—are key selection criteria for selecting a wipe-impregnated disinfectant to clean surfaces in the pharmaceutical and biomedical industries. Not surprisingly, knitted polyester seems to be the most suitable fabric for these applications.

Cooper pointed out that if the single-use cleaning products used in pollution control cause an additional 0.1% loss of output compared to the best choice, then this means a $1 billion semiconductor production line will lose $1 million in value.

A disk drive manufacturer uses unwashed knitted polyester wipes to save on wipes costs. As a result, the contamination from the unwashed wipes forced the entire production line to be shut down and costly cleaning operations performed with suitable wipes.

When deciding which wipe to use, it should be clear which properties are most important and which properties can be discarded. In Howard Siegerman, Ph.D., more consideration should be given to the nature of the contamination than the effect of cleaning, as the generally accepted medical standard says: "First, do not cause harm."

Cooper describes a multi-objective decision-making procedure to aid in the selection process. Likewise, Atterbury et al. and Cooper describe a method for selecting some attribute values for edgebanded, washed knitted polyester fabrics as baseline attribute values.

The method considers ten different criteria:

Releasable particles, fibers, abrasion resistance, non-volatile residue content in water and isopropanol, releasable sodium and potassium chloride, water absorption, water absorption rate.

They tested ten samples of five different wipes and calculated the mean of each test for each type of wipe. The lowest mean for each test is determined as the benchmark value, and all means are divided according to this lowest mean.

In this way, through a series of tests, a graphical and visual comparison of various types of wipes can be made.

Categories

New Blog

Copyright © 2024 Nanan Jiedao Electronic Material Co.,Ltd.. All Rights Reserved. Powered by

IPv6 network supported